Welcome to Haichen

Automatic Coating and Dispensing Solution

- Full-line SMT equipment supplier

- Serves customers globally

- Fast response

- Customer focus

Welcome to Haichen SMT

Haichen SMT is a global leader in providing state-of-the-art SMT equipment and full-line solutions for PCB assembly. With a commitment to quality, innovation, and customer satisfaction, we offer a complete range of products, including high-speed dispensing machines, selective coating machines, UV curing ovens, and more. Whether you are looking to enhance your production capabilities or streamline your manufacturing process, Haichen SMT has the solutions you need to succeed.

Explore Our Products

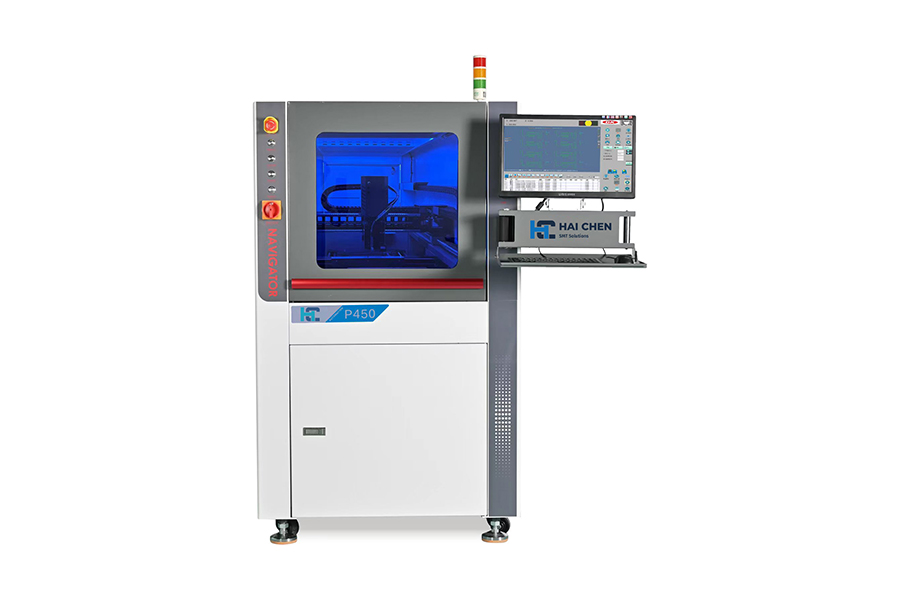

The High-Speed Dispensing Machine by Haichen SMT is designed for precise and rapid application of adhesives, solder pastes, and other fluids onto PCBs. The machine offers flexible programming options and supports various dispensing patterns to meet diverse assembly requirements.

Haichen SMT’s Selective Coating Machine provides advanced, automated solutions for applying conformal coatings to specific areas of a PCB. This equipment ensures protection against moisture, dust, chemicals, and temperature variations, extending the lifespan of sensitive electronic components.

The UV Curing Oven by Haichen SMT offers a fast and efficient way to cure coatings, adhesives, and other UV-sensitive materials used in PCB assembly. This energy-efficient furnace is perfect for production lines requiring quick turnaround times without compromising on quality.

The PCB Lift Conveyor is an essential tool for the safe and efficient handling of PCBs between different levels in an assembly line. It ensures smooth and precise vertical transportation, reducing the risk of damage and maintaining a continuous workflow.

Haichen SMT’s PCB Conveyor is designed to streamline the connection between different PCB handling systems within the assembly line. It enables the seamless transfer of PCBs between various machines, reducing production bottlenecks and ensuring smooth transitions.

The PCB Flip Conveyor is a versatile solution for changing the direction of PCBs within the production line. It enables smooth 90-360 degree turns, making it ideal for optimizing factory layouts and ensuring efficient use of space.

Why Choose Haichen

At Haichen SMT, we pride ourselves on being more than just a supplier of advanced SMT equipment—we are your partner in achieving manufacturing excellence. With a strong commitment to innovation, quality, and customer satisfaction, we provide solutions that help our customers stay ahead in the competitive world of PCB assembly. Here’s why you should choose Haichen SMT as your trusted partner:

Industry Expertise

With years of experience in the SMT industry, Haichen SMT has a deep understanding of the challenges and opportunities faced by EMS manufacturers.

Advanced Technologies

Our state-of-the-art equipment is designed to meet the demands of modern manufacturing, ensuring that you stay ahead of industry.

Quality and Efficiency

Every machine is built to deliver reliable, consistent performance, ensuring that your production line operates smoothly and efficiently.

Customer Focus

From initial consultation to after-sales support, our team is dedicated to providing exceptional service and building long-term relationships with our customers.

Trusted Clients

What Our Customer Say

Frequently Asked Questions.

Haichen SMT provides a wide range of advanced SMT equipment, including high-speed dispensing machines, selective coating machines, UV curing furnaces, and various SMT peripheral equipment such as PCB lift machines, PCB docking stations, and PCB turning conveyors. We also supply high-quality SMT spare parts to support ongoing operations.

Yes, we specialize in providing tailored solutions to meet the specific needs of each customer. Our team works closely with you to understand your production requirements and design a solution that maximizes efficiency and productivity. This includes customizing equipment configurations, optimizing dispensing patterns, and integrating our machines into your existing production line.

We provide comprehensive support services, including installation, training, technical support, and preventative maintenance. Our goal is to ensure that your equipment operates at peak performance throughout its lifespan. Our global support network ensures that you receive timely assistance, no matter where your facility is located.

Yes, we offer equipment demonstrations to help you better understand the capabilities and performance of our products. You can schedule a demo at our facility or request a virtual demonstration. Please contact our sales team to arrange a demo session that fits your schedule.

You can order spare parts directly through our website or by contacting our customer service team. We maintain a large inventory of genuine, high-quality spare parts to ensure fast delivery and minimize downtime. If you need assistance in identifying the right part, our team is here to help.